Unsavory, but true: bacteria are ever-present in the soil, air, water, and foods we eat. And when bacteria have nutrients (food), moisture, time, and conducive temperatures, they can multiply rapidly to the point where they can cause illness.

Leaving food out too long at room temperature can cause bacteria—such as Staphylococcus aureus, Salmonella Enteritidis, Escherichia coli O157:H7, and Campylobacter —to grow to dangerous levels that can cause illness. And while heat kills most bacteria, some toxins are heat resistant and not destroyed by cooking.

Best Practice: Normally, a large number of food-poisoning bacteria must

be present to cause illness. Foodborne illness can be prevented by:

- Controlling the initial number of bacteria present

- Preventing the small number from growing

- Destroying the bacteria by proper cooking

- Avoiding re-contamination

For multi-unit operators, understanding the critical role temperature plays in keeping food safe is crucial. Unsafe temperature conditions can occur due to equipment malfunctions, power outages, improper closing of cold room, refrigerator, or freezer doors, as well as staff errors. Having to discard perfectly good ingredients and inventory due to incorrect storage temperatures is a huge and preventable loss that inevitably affects the business's bottom line.

To safeguard against such scenarios in a highly competitive industry already running on narrow margins, restaurants, grocery, and convenience store operators are increasingly relying on temperature monitoring sensors to mitigate food safety breaches. Digital temperature monitoring sensors are proving to be game-changers in kitchens by reducing human error, improving operational efficiencies, eliminating food waste, and keeping food, guests, and business healthy and safe.

By the time cooks and chefs start in-store food prep, their ingredients have already been through an intensive journey. From cultivation, production, and transport to storage and preparation, keeping food safe throughout the chain is an intricate process that requires rigorous standards during each stage to meet food safety regulations.

Food preparation further requires thawing, chopping, mixing or marinating, cooking, cooling, holding, serving, or reheating. Every step has bacteria growth dangers, making it essential that kitchen staff work quickly.

With the potential for error ever-lurking in the food safety chain, there are some key areas where operators have control to reduce the risk of foodborne illness. One of these is temperature control. By automating this food safety process, operators save employees time by eliminating manual temperature checks and ensuring compliance with internal and government safety standards.

The Danger Zone

Storing, preparing, and serving food at the right temperature is a critical aspect of food safety. With so many variables, from handling the ingredients to preparing the food to ensuring equipment is functioning optimally, mistakes are bound to happen with potentially costly and damaging consequences.

With over 85% of food safety concerns arising due to poor food and storage temperature management, it's imperative for food to be kept out of the "danger zone"—the temperature range where food is most at risk of developing harmful bacteria.

Most bacteria do not thrive in hot or cold temperatures above or below the danger zone (40°F and 140 °F). The longer food remains in the temperature danger zone, the greater the risk of "time/temperature abuse" and bacterial growth resulting in foodborne illness.

Best Practice: It is recommended to check the temperature of hot or cold holding food every four hours. However, checking it every two hours instead will allow enough time to take corrective action in the event that food has fallen into the danger zone.

Hot Food

The appropriate holding temp for hot foods is 140°F or above. Time/temperature abuse happens when food is not stored or held at safe temperatures, and hot food is not cooled appropriately before going into cold storage. It also occurs when food is not cooked or reheated to the required temperatures to eliminate pathogens.

Surprisingly, improper cooling of cooked, hot food is one of the most common causes of foodborne illness. Even after food has been cooked to a safe temperature, bacteria can re-emerge and reproduce, growing rapidly in temperature settings between 40°F and 140°F. Bacteria can double within 20 minutes in this temperature range.

Cold Food

Any cold food held without refrigeration is safe for up to six hours, starting from the time it was removed from refrigeration at 40°F and below. It's important to know how long you can store cold foods before they become unsafe for consumption. Food safety labeling and dating is a recommended practice - always date label your refrigerated foods and use a first-in, first-out (FIFO) approach. Only the necessary quantities should be removed from cold storage during prep.

Best Practice: Don't let certain foods— particularly starchy foods, cooked and cured meats, cheese, and meat salads—sit at room temperature for more than two hours.

TCS Foods

Time/Temperature Control Safety (TCS) foods are specifically prone to bacteria growth and require close monitoring and regular temperature checks. TCS foods include milk products, meat, poultry, seafood, eggs, baked potatoes, cooked rice, soy proteins (such as tofu), untreated garlic and oil combinations, melons, tomatoes, and greens that have been cut.

These foods need to be kept at safe temperatures before and after cooking and must be cooked to a predetermined minimum internal temperature, checked with a food thermometer. These probes should always be sanitized and regularly checked for accuracy. They must be inserted into the thickest part of the food and left for a few seconds until the reading stabilizes for an accurate temperature reading.

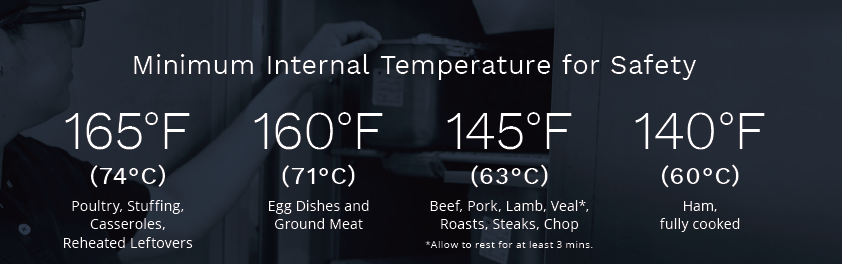

Food safety regulations require raw poultry to be cooked to an internal temperature of 165°F, raw ground beef and pork to 160°F, and raw beef steaks, veal, pork, and lamb chops to 145°F. These are all minimum temperature regulations.

Best Practice: High-risk foods should not be at room temperature for longer than two hours during kitchen preparation.

Gaining a Competitive Advantage

Foodservice operators are gaining a competitive advantage by investing in automated temperature monitoring. It's easily scalable, meaning operators can use digital sensors in one location only or across multi-location chains. They can be configured with predetermined thresholds and time frames. Preventative alerts will allow proactive intervention before a problem turns into a crisis. District managers can get real-time insights into each of their stores' temperature data.

Zenput offers an efficient way to monitor temperatures with remote access to temperature information and real-time updates, so staff is alerted instantly if stored and cooked food or equipment go out of range. Zenput's Temp Monitoring solution automatically logs digital temperature readings at regular intervals and in real-time, easily accessible via mobile device or computer.

Download The Operator's Guide to Food Safety Execution to learn how Zenput can help your operation improve food safety and compliance to better protect your inventory, customers, and staff from foodborne illness, guaranteeing safe and quality meals.

Subscribe to our blog

You are now subscribed!